Computer Numerical Control (CNC) laser tube cutters have revolutionized the manufacturing industry by transforming concepts into reality. These advanced machines use laser technology to accurately and precisely cut tubes made from various materials, including metal and plastic. From simple designs to complex shapes, CNC laser tube cutters can bring any idea to life.

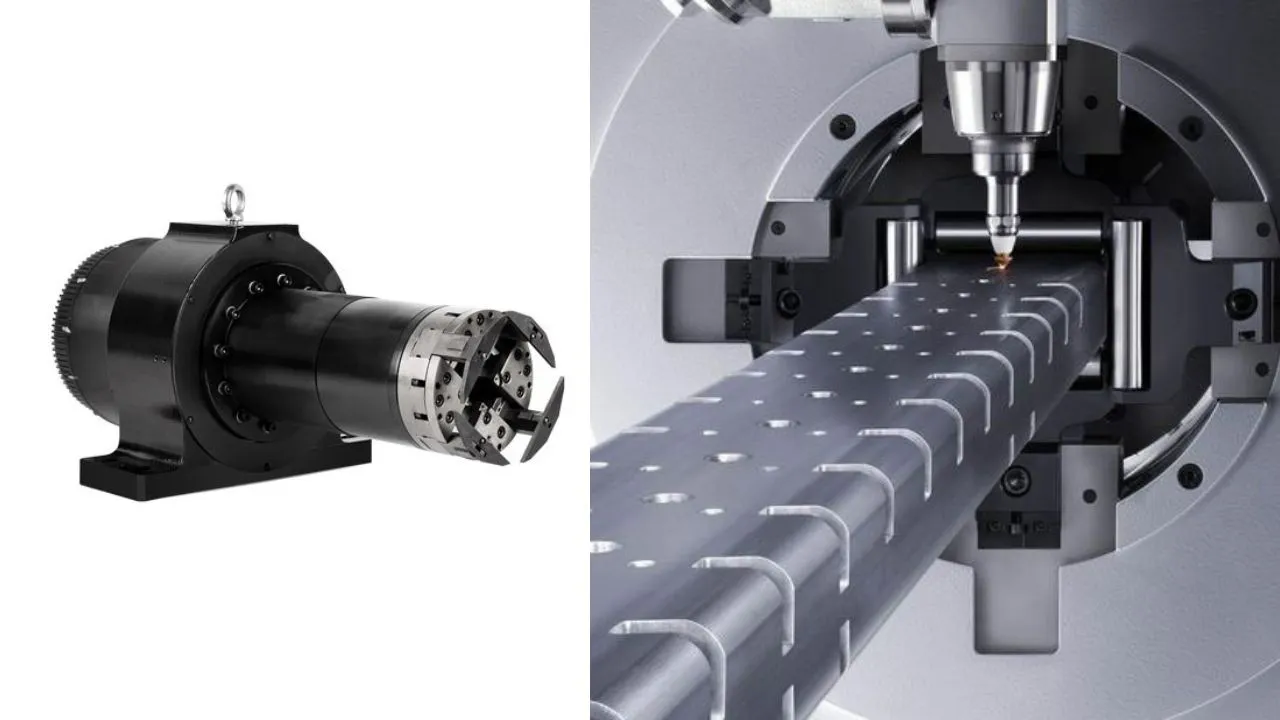

One of the most significant advantages of CNC laser tube cutters is their ability to cut tubes in three dimensions. Traditional cutting methods can only achieve two-dimensional cuts, limiting the design possibilities. However, with CNC laser tube cutters, manufacturers can create intricate and precise cuts that were previously impossible.

The precision of CNC laser tube cutters is unmatched. These machines can cut tubes with incredible accuracy, ensuring that the final product is precisely as designed. This level of precision is crucial in industries such as aerospace and medical, where even the slightest deviation can have severe consequences. CNC laser tube cutters eliminate the risk of human error, resulting in flawless cuts every time.

Furthermore, CNC laser tube cutters offer a high level of automation. Once the design is programmed into the machine, it can work continuously without human intervention. This automation not only increases productivity but also reduces labor costs and speeds up production times. Manufacturers can now produce more products in less time, giving them a competitive edge in the market.

The versatility of CNC laser tube cutters is another reason why they are becoming increasingly popular in the manufacturing industry. Whether it's cutting straight lines, curves, or complex shapes, these machines can handle it all. They are capable of cutting tubes of various diameters and thicknesses, making them suitable for a wide range of applications.

CNC laser tube cutters are widely used in industries such as automotive, construction, and furniture manufacturing. In the automotive industry, they are used to create exhaust systems, roll cages, and frame components. In construction, they are used to fabricate handrails, staircases, and architectural elements. In the furniture industry, they are used to create unique designs and patterns on metal and wooden tubes.

Another advantage of CNC laser tube cutters is their speed. These machines can cut tubes at a much faster rate compared to traditional methods. This increased speed not only improves productivity but also allows manufacturers to meet tight deadlines and satisfy customer demands. CNC laser tube cutters are a game-changer for businesses looking to streamline their production processes.

Moreover, CNC laser tube cutters are environmentally friendly. They generate less waste compared to other cutting methods, reducing material costs and minimizing the impact on the environment. Additionally, the laser technology used in these machines consumes less energy, making them more sustainable and cost-effective in the long run.

As technology continues to advance, the possibilities of CNC laser tube cutters are only expanding. Manufacturers are continually finding new and innovative ways to utilize these machines, pushing the boundaries of design and manufacturing. With their ability to turn concepts into reality, CNC laser tube cutters are undoubtedly a game-changer in the manufacturing industry.

In conclusion, CNC laser tube cutters have transformed the manufacturing industry by providing unmatched precision, automation, versatility, and speed. These machines have opened up a world of possibilities, allowing manufacturers to bring their concepts to life. From simple designs to complex shapes, CNC laser tube cutters are revolutionizing the way we create and produce. The future of manufacturing is undoubtedly brighter and more efficient with CNC laser tube cutters.